This is a nice little case that goes from diagnosis to final restoration, “tag teaming” between CEREC to Galileos for case planning, back to CEREC for CEREC Guide fabrication, then back to CEREC again to fabricate an Emax screw retained abutment crown for a Legacy 3 implant. patient had a failing endo that (against my advice) had an apico that lasted 2 years then failed again. Out came the tooth with a little “ground up dead person ” (human DFBDA cadaver bone) and a membrane and after 2 month we planned for an implant.

As always I like to plan my cases both with and without the CEREC proposal just to get a feel for where the implant is relative to the ridge and adjacent contacts. Remember, the Tangential view is made up of 1mm slices, so you may think you are close is some areas, but are really more palatal or buccal, so scroll through the plan and always check back with the 3D.

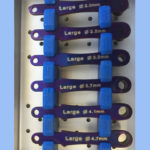

Easy case using a 4.7 by 13mm Legacy 3 implant. Not the stability I would like (>35Ncm) as the bone was too immature. I am waiting 3 month now, before was 8 weeks.

Don’t remember my rationale for using the cover screw and collar that comes with the Legacy, maybe I didn’t have a larger healing abutment. But it was my past self thinking, so it must have been a valid reason ;}

Ok so here is a pet peeve of mine with the scan posts: contacts. The post is usually so long and at times, with the grey scan cap, the space is so tight that I can’t get into the contacts to image well. So on some cases I have been taking a physical model. Well, lookie here!!! Go to the Gingival Mask, take your first set of images without the post or the healing abutment. Then COPY that to your upper or lower model depending on what you tooth you are working on. Now use the CUT tool and just cut out where the scan post will go. Next scan the post. Your contacts will be INTACT!!!!! So awesome!

You can see in the actual models how nice of contacts we have. You can really get down into the area below the heights of contour this way!! Milled out an A3 size 16L block!

Try the Emax in the mouth, everything looks good. Note the difference between the freebie Ti-Base screw and the actual manufacturer screw. You can see that the real implant screw is much more robust and it is longer. Now that being said, if you are hurting for space, you may want to use the shorter ti-base screw.

I just love the Multi Link Hybrid Abutment cement!! Its like white out! Another helpful hint is if you have any implants that end up in the Box of Shame (where dropped or failed implants go in my practice) you can use them as implant analogs. We sometimes re use analogs so we just throw them in a jar still in the pindexed die and put them in a lab box if we are sending them out. In this case I just used it so that I could cement the crown to the abutment.

Just a little progression image. I’m actually a little bummed. You can see the screw access in my plan and I am a little deviated to the buccal! Sort of a party foul as its still fairly centered but I lost style points on this one. I would blame the fact that my graft was soft or I did not do the case fully guided as I placed the implant by hand. Either way I am still happy with my end result.

And here it is. A little sponge in the access. I have been playing around with Diashine and working on an Emax abutment finishing kit. I like to stain and glaze, then I go back over my buccal and lingual with a while and the pastes just to make it more awesome. A little bit of flash on the occluso-buccal that I got later, but overall, I think I did not go too crazy with the ochre stain. On anther note. Look at the endo access through the PFM on the neighbor tooth. Now I know its old and stained, but look at the opacity difference. Now look at the access on my screw retained crown, big difference due to the translucency of Emax! There is just nothing cooler in dentistry than planning, placing AND restoring the implant that YOU did!