Here is a case that really went smoothly. Fractured molar, non restorable. Planned for CEREC Guide.

Here is a case that really went smoothly. Fractured molar, non restorable. Planned for CEREC Guide. As I was waiting for the Galielos scan to load I did a quick quadrant scan in CEREC.

As I was waiting for the Galielos scan to load I did a quick quadrant scan in CEREC.

This never happens right? Furcation bone, greater than 11.5mm. Planned a Legacy 4 7 by 11.5.

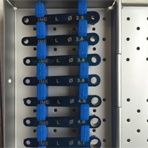

Milled out the CEREC Drill Body and assembled.

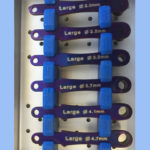

As always, I drill through the furcation first with a carbine 557, then place the guide and drill into the furcation bone with the initial 2.3mm pilot using my handy dandy IME key set.

After removing the roots, then proceed as usual through the drill series.

The 7mm drill requires that you use the crystal bone drill to shape the socket. ID was out of HA coated in the 7mm (damn I should have not been such a big promoter of these!) so I went with SBM

Awesome torque values if you do it right. Gaps on Buccal and Palatal that need to be filled.

Packed some DFDBA, did my little “hole in membrane trick” and packed the membrane down with one of my tools. The cover screw or healing abutment tacks down the membrane so you can suture around it.

Here we are about 4 months later. Replaced the cylindrical healing abutment with a contour healer. Really helps in the design process with CEREC 4.3 and drawing the base line.

16 L LT Emax block milled while the patient waited. Everyone is different but I really like to try the Emax in on the blue state just to make sure everything fits before sintering and attaching to the tibase.

Everything fits well. You can see the screw access in the central fissure. Cemented with Multi Link Abutment on the Ti-base after micro etching.

Loving teflor tape. I even think it opaques a little too good. You can see my access fill is a bit too high in value. Tried to get all fancy with the ochre stain. Love this stuff.