Here is a 2 unit case done in CEREC Guide. I had heard that if you cooled the water in the milling unit and added ice you could speed up the milling process. Patient just finished Invisalign and wanted teeth in there ASAP, so we planned the case for some CEREC Temps, then we will make her a retainer. #9 and 10 are implant temps from before.

Great in theory not in practice. Even though the mill preview always tells me about 13 minutes it usually takes 20. With the ice it shaved off 3 minutes. Not enough to write home about.

When I do multiple unit cases I usually like to use two different sized reference body so as to not get the Drill bodies messed up. In this case the edentulous spaces would not allow that so I made sure to mill one, place it in the thermoplastic, the mill the other and finish the guide.

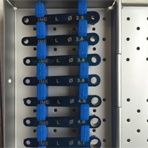

Nice and easy case. Lots of attached tissue. My Zimmer/ID compatible keys worked great. Just got word that another prototype is on its way then I can start producing them. Just working on the sterilization cassette design.

Implants placed in the center of the edentulous spaces and indexed.

Implants placed, not in love with #13 but in retrospect, thats how I planned it and as you can see in the mouth, it still turned out easy to restore. Torqued down at 30 Ncm, although I think I will use custom abutments on these in 4 months.

CEREC “Temps” made. Due the the cylindrical nature of the abutments the crowns seemed a bit bulky and “ridge lap-y” so custom abutments would allow for a more constant emergence profile.