The Emax CAD abutment blocks are taking digital dentistry to another level! The material is so easy to work with, is esthetic, and now part of implant dentistry. We review the use and efficiency of Emax in all of our Cerecology courses.

Nobel Biocare Wide Body implant placed and integrated.

Healing abutment removed and TiBase placed. (This was completed at a time before the “Scan Posts” were available. The advantage to a Scan Post is that it is taller and easier to place.)

Verification of seating with an X-ray. I do this when taking physical impressions, and using a Scan Post.

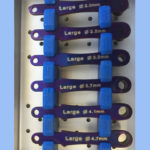

The “Scan Body” is placed. Make sure this plastic part is placed correctly. It can easily miss the anti-rotation portion of the TiBase or Scan Post.

The digital model is made and the point of the Scan Body is marked for orientation.

The Biogeneric calculation is completed, and the screw access is shown in red.

The angulation of the implant can be compared with the proposed restoration. This is the time where you can “split” the restoration into an abutment and crown if desired.

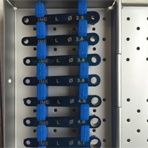

The Emax CAD Abutment block is ready to be milled. This block ALREADY has a hole milled into it. The milling chamber does not mill the hole for the interface to the TiBase.

After milling and crystallization of the Emax Hybrid Crown/Abutment, it can be bonded to the TiBase. This is done with Ivoclar-Vivadent’s new Multilink Hybrid Abutment cement. Both the ceramic and the metal TiBase are treated with Ivoclar-Vivadent’s Monobond Plus silane. The cementation of the Emax restoration to the TiBase is done extra-orally.

The entire unit is taken to the mouth and screw retained, and closed with a cotton pellet and Tetric Evo Ceram.

X-ray after completion.