Have you ever asked yourself what the heck is happening when you are scanning for a digital impression? It’s a really cool process so let’s take a look! The CEREC Primescan is the most up to date camera on the market and the flagship of the Dentsply Sirona CAD/CAM arsenal.

Have you ever asked yourself what the heck is happening when you are scanning for a digital impression? It’s a really cool process so let’s take a look! The CEREC Primescan is the most up to date camera on the market and the flagship of the Dentsply Sirona CAD/CAM arsenal.

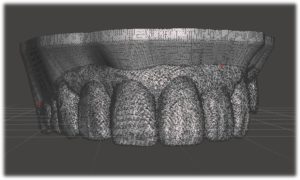

As we pass the camera over our patients teeth, it is processing 1,000,000 3D points per second with the ability to reach a depth of 20mm accurately. It is consolidating 50,000 images per second. Let all of that sink in for a minute. The bottom line is this awesome technology is taking in a ton of information and quickly translating it into what we see on screen as a digital rendering of a patients dentition.

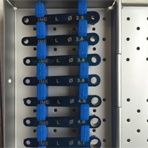

What exactly are these digital renderings though and what do we do with them? Once we have all of the information collected, we have several options. We can fabricate restorations. We can transfer these images as a .STL file which is an abbreviation for steriolithography, Standard Triangle Language or Standard Tessellation Language.This format has been around a long time with CAD design in the engineering sector. The .STL file is the precursor to everything else we are doing in digital dentistry; digital wax ups, 3D models, implant planning all incorporate this file type. STL’s are no different than alginates, poly-vinyls, or poly-ethers in today’s dental practice. The method used to get our model from them does vary greatly. With the latter, stone models were poured with bases and trimmed on a model trimmer. This process is quite messy and loud, not to mention the dreaded bubbles that can occur in our pour up. STL files allow us to do the dirty work on a computer and then 3D print the models for conventional purposes. Once the images have been captured you can manipulate them with different programs such as Meshmixer and Exocad.

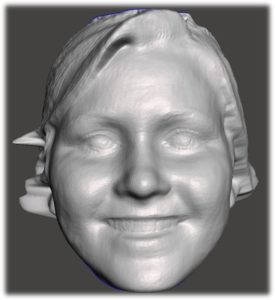

When we strip down a STL to its basic form it is called a wire frame. These wire frames are multiple triangles, that are multiple sizes, in multiple planes creating our 3D rendering of the

When we strip down a STL to its basic form it is called a wire frame. These wire frames are multiple triangles, that are multiple sizes, in multiple planes creating our 3D rendering of the

subject. These subjects can literally be anything. If you can scan it you can convert it to a STL file. The applications are endless. Once the basic wire frame is created, the programs make them solid and most color them to make our eyes understand what we are seeing. Manipulation of these solid models are very easy in these programs as well.

Now that you know what a STL file is and how to get them, the real fun begins! This basic concept allows you to work outside normal parameters and figure new ways to move digital dentistry forward to improve patient care. The ability to show patients their teeth on a screen and manipulate things fascinates and intrigues them. This shows that you are moving forward with our tech thirsty society and making strides for better and more efficient patient care. Digital impressions, 3D printing, guided implantology, and other emerging digital concepts are here to stay so I suggest you learn as much as you can and have fun while you are doing it!

Now that you know what a STL file is and how to get them, the real fun begins! This basic concept allows you to work outside normal parameters and figure new ways to move digital dentistry forward to improve patient care. The ability to show patients their teeth on a screen and manipulate things fascinates and intrigues them. This shows that you are moving forward with our tech thirsty society and making strides for better and more efficient patient care. Digital impressions, 3D printing, guided implantology, and other emerging digital concepts are here to stay so I suggest you learn as much as you can and have fun while you are doing it!