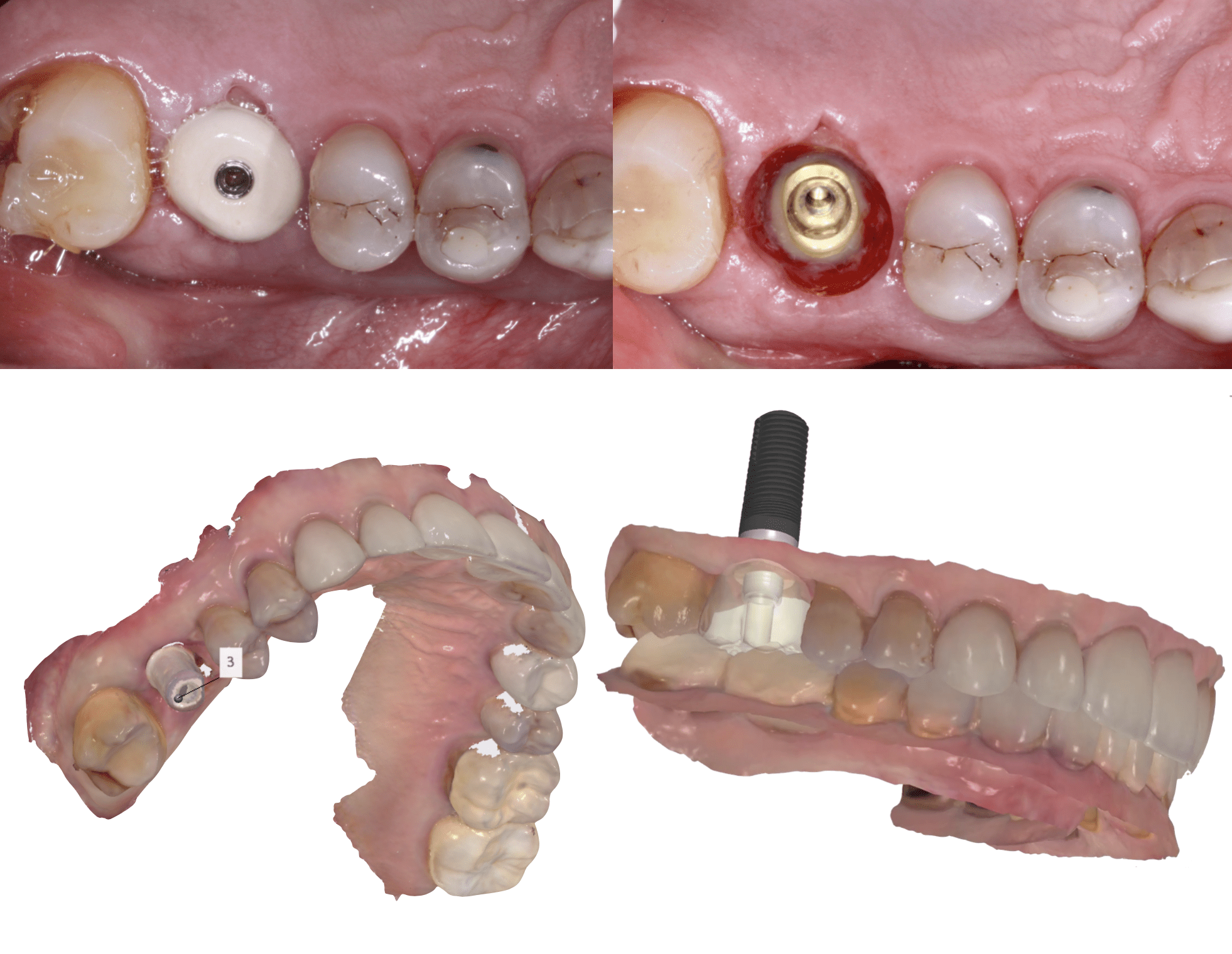

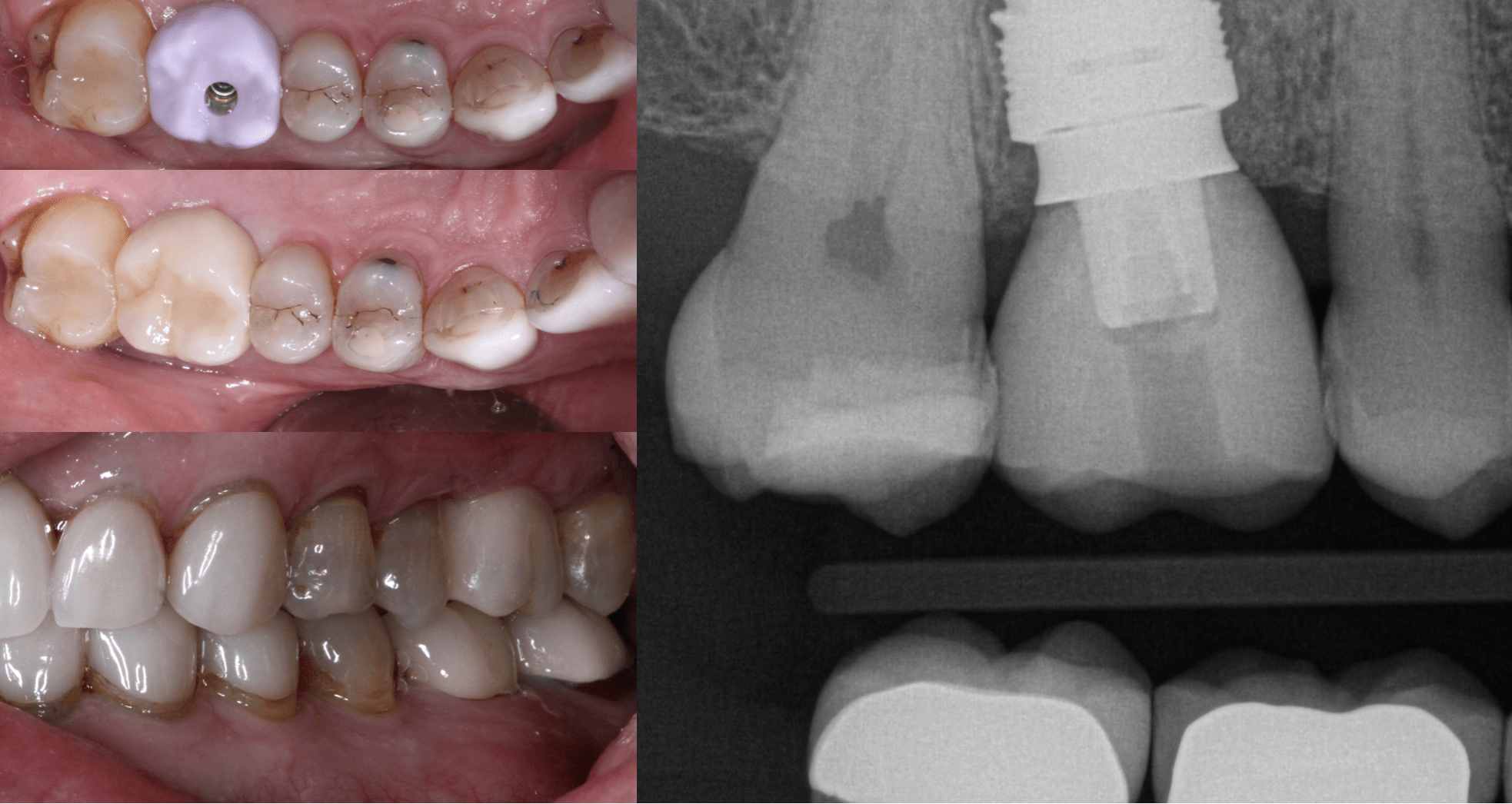

This was a super easy case that was made even easier using the VHF mill and the new Implant Direct Smart Base system of ti bases. Placed contour healer 3 weeks ago. Tissue still maturing so maybe should have left another week. As you may or may not know the contour healers are engaging and looks like my timing should have been rotated a little bit but still did not need to laser the tissue. Designed for a screw retained emax crown using a 5.7mm smart base with a 2mm gingival height.

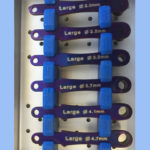

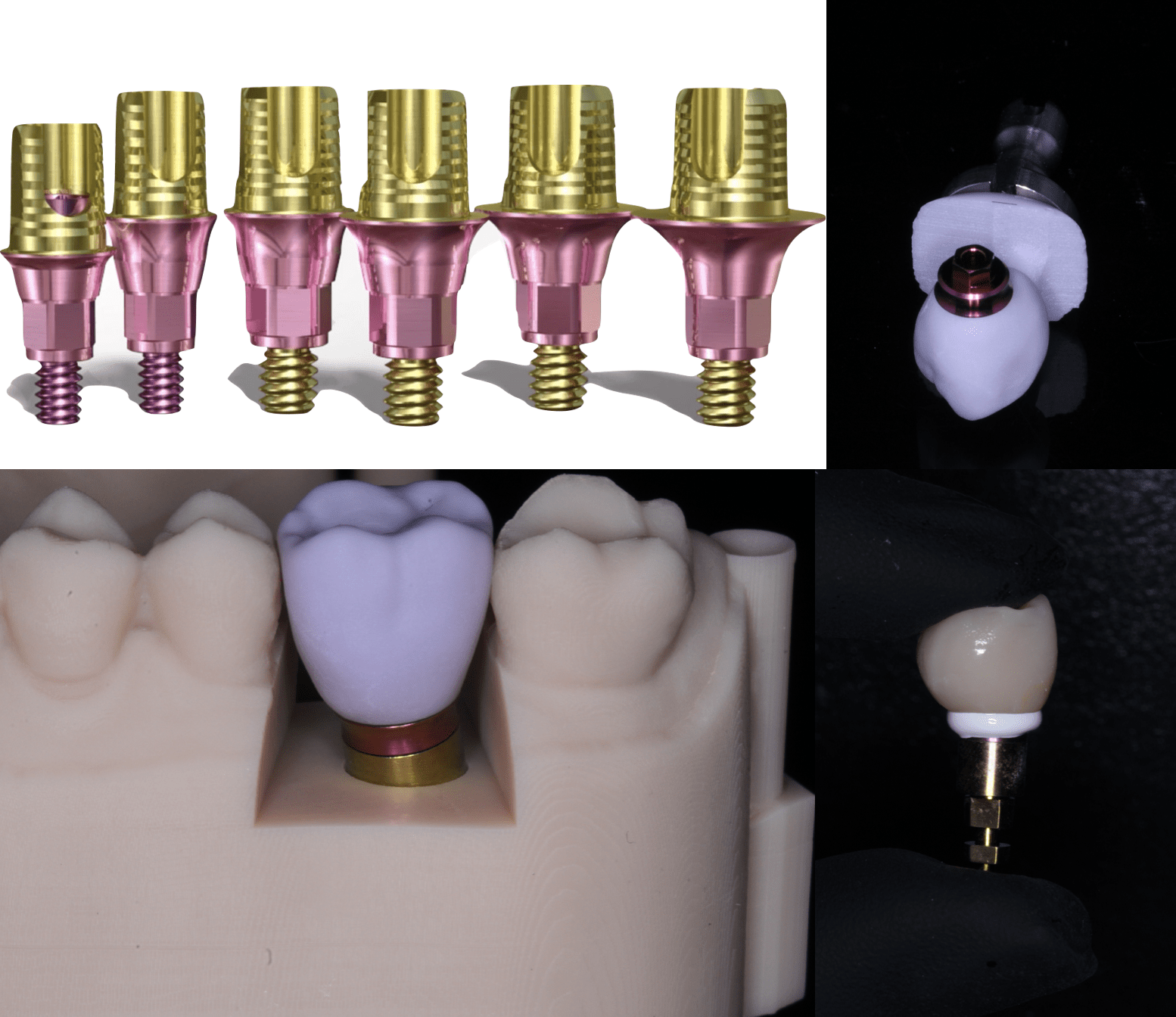

These smart bases are sick! Most of his that mill in house are used to some pretty blah ti bases. No platform switching, gray shiny metal and a 0mm gingival height make these tough for subcrestal implant placement. You have to remove a lot of bone and lose a lot of the benefits of platform switching. Plus they are gray! The new Smart Bases are pink in the gingival and gold in the part that cements to the ti base. They come in 0,1 and 2mm gingival heights that are concave to allow better bone and tissue growth. Printed a model on the Asiga Max printer using the new implant direct 3D analogs. The Emax crown was milled in 20 minutes using a standard 14 CEREC block on the VHF Z4 mill. Cemented with Ivoclar Multilink Hybrid abutment cement.

I know my staining could use some work. Love the collar in the subcrestal bone.

We are doing a CEREC Live Patient Implant Course in Phoenix where we will cover CEREC Guide 2, Scanning with Scan Posts for Abutments and Crowns, as well as demoing full arch scanning with Primescan and Digital Dentures! Feb 20-22 2020. If you are a Trios user we can adapt the hands on for you!

If you want to know how to make guides, aligners, digital dentures and more, come to a 3D Printing party!! Jan 17-18 in Minneapolis!!

https://www.eventbrite.com/e/dental-3d-printing-party-minnesota-tickets-68513003237

We are also doing one in Richmond VA April 17-18!

https://www.eventbrite.com/e/dental-3d-printing-party-richmond-va-tickets-89491999981