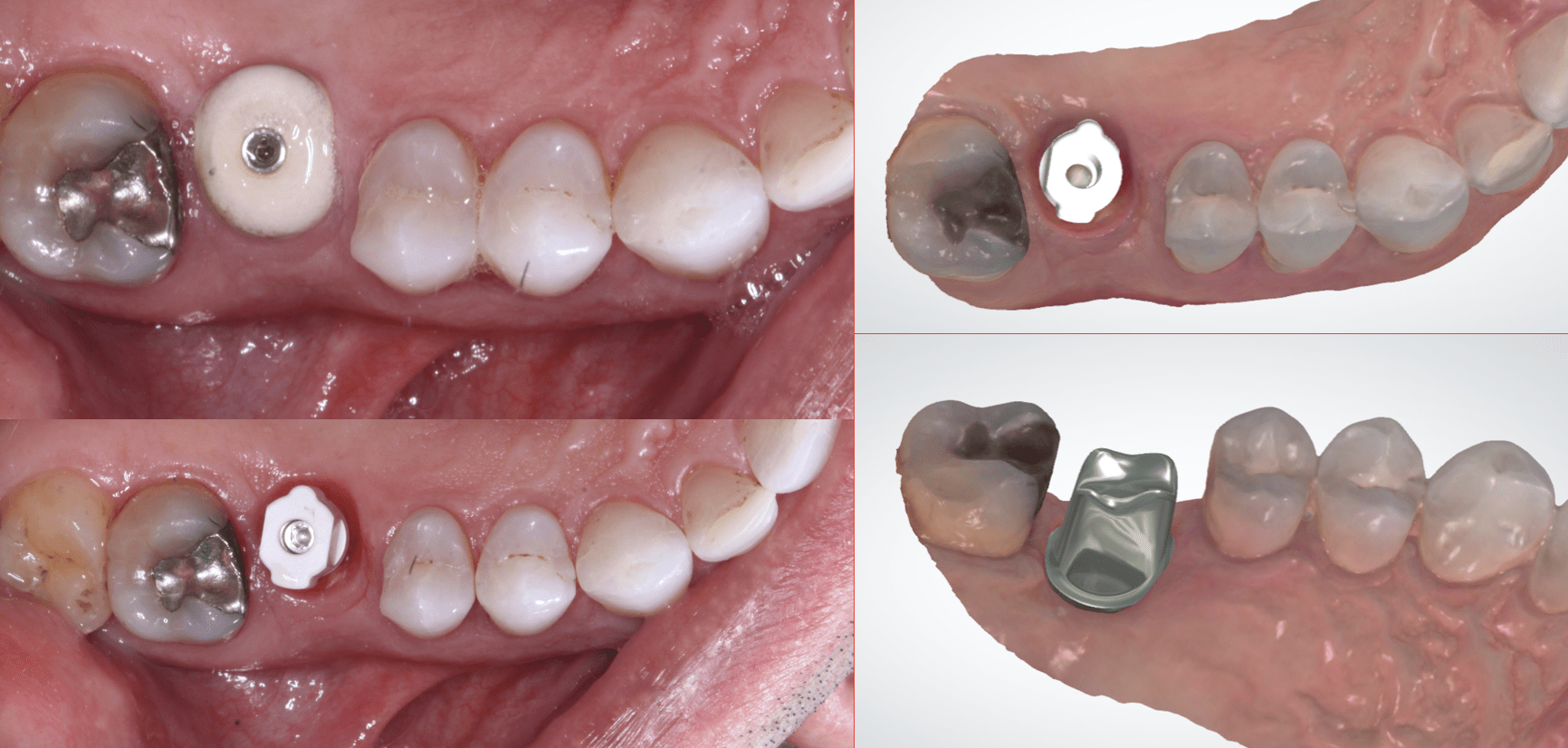

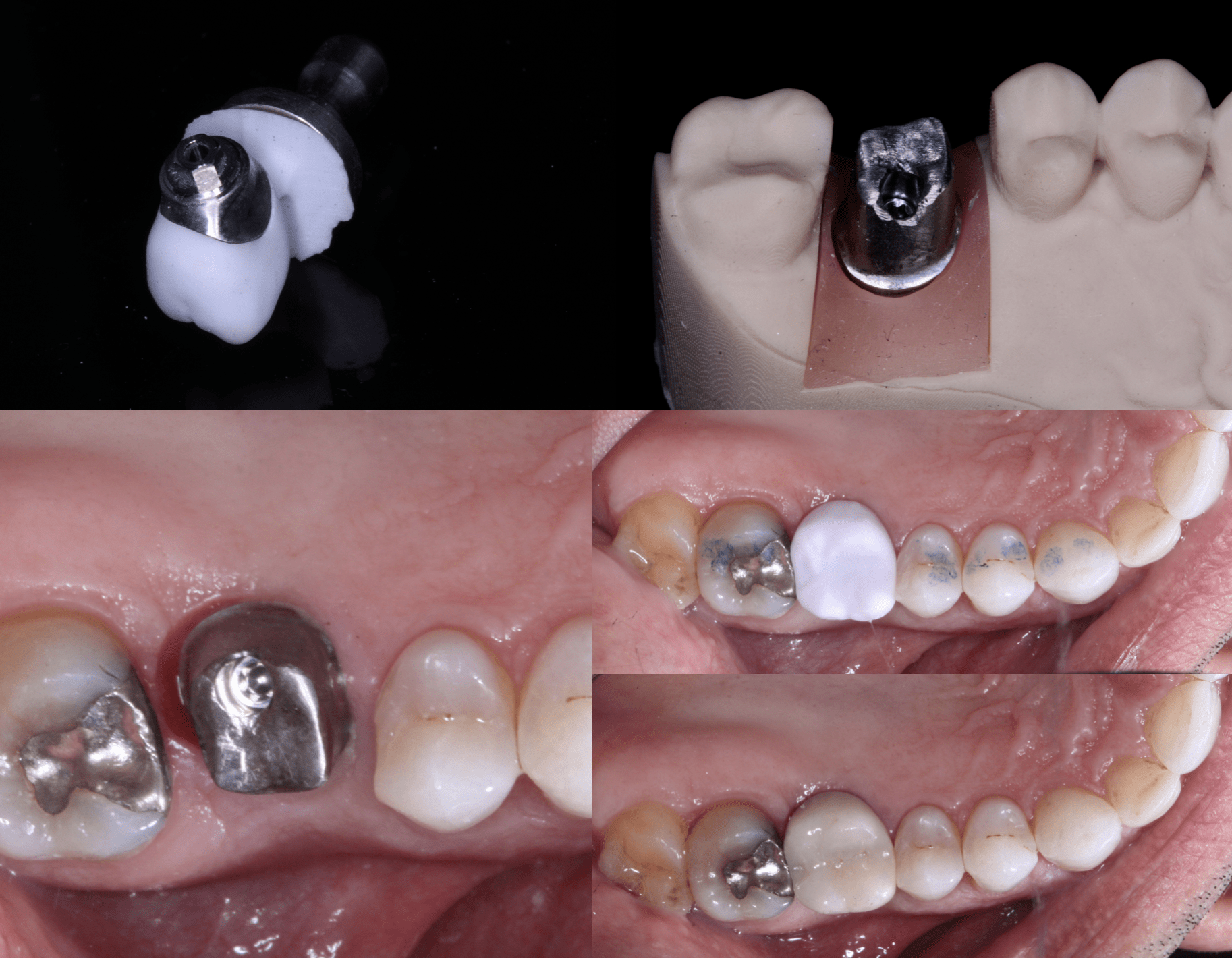

Here is another fun case with the Trios/VHF Z4 Chairside set up I am testing for Patterson. While I never personally had an issue with ti bases debonding, many are a little wary as ti bases are short and really don’t have much in the way of ferrule. A number of digital docs are having custom abutments made and cementing either an Emax crown, or a crown with a hole in it for a Screwmentable restoration. Trios Chairside Design studio does not have abutments yet, I just saw the screw retained module, so I had the illustrious Jacob Farber design this for me and did it in two appointments.

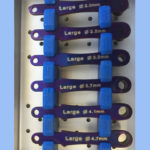

Up until now I have been used to milling “blocks with holes in them”, for ceramic abutments, but one thing cool about the Z4 is that it can mill abutment blanks from either NT Trading or DESS. The internal connection is pre milled for you and it takes about 20 minutes to mill the abutment shape and another 20 minutes to mill the Emax. You could do this as a one appointment deal, but did it in two.

Really like the shiny metal shader on Trios!

Here is the blank in the machine with the carbide bur block.

Tried in the abutment and Emax in the purple state to make sure there was no occlusion and it fit great! Definitely adding this to my Implant Restorative Armamentarium!!

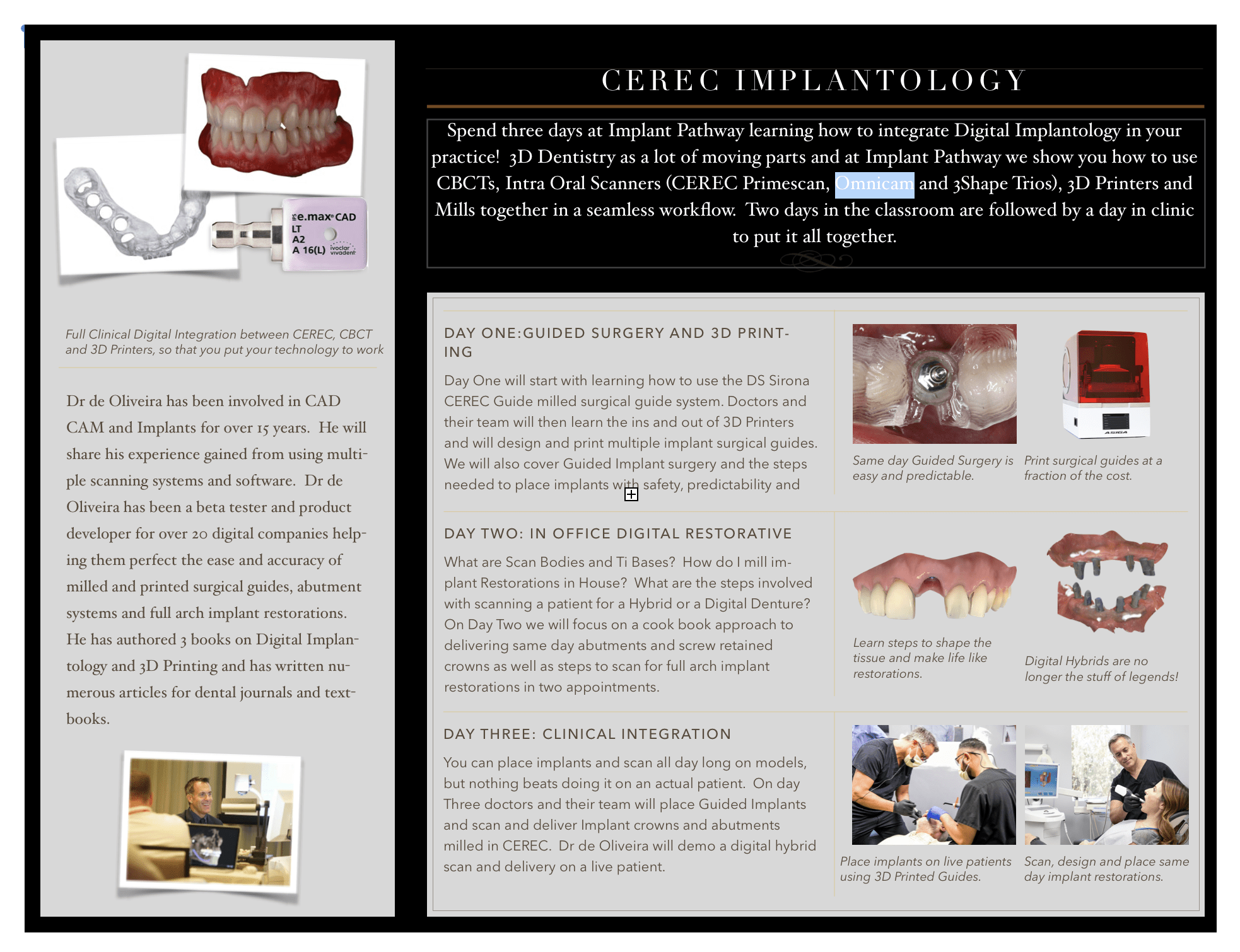

We are doing a CEREC Live Patient Implant Course in Phoenix where we will cover CEREC Guide 2, Scanning with Scan Posts for Abutments and Crowns, as well as demoing full arch scanning with Primescan and Digital Dentures! Feb 20-22 2020. If you are a Trios user we can adapt the hands on for you!

If you want to know how to make guides, aligners, digital dentures and more, come to a 3D Printing party!! Dec 13-14 in Minneapolis!!

https://www.eventbrite.com/e/dental-3d-printing-party-minnesota-tickets-68513003237