One of the big advancements in CAD/CAM dentistry materials was the launch of the Multiblock from Ivoclar Vivadent in 2007. It was from their very popular line of Empress CAD blocks and pressed material. They were able to make a block with a varying degree of translucency. The shade stayed the same, but translucency increased. Even while more translucent, it still retained good fluorescence which kept it from looking grey.

This gentleman had prior Ivoclar Vivadent products as crowns: Empress 2. They were made in the early 2000’s. Empress 2 was actually the precursor to the IPS eMax that we use today. It had the lithium disilicate core (Empress 2) with pressed Empress (feldspathic ceramic reinforced with leucite) over it. In 2007, he wanted his teeth to be whiter, and his crowns to match. After bleaching, the crowns appeared yellow, and they were replaced with the recently launched Empress CAD Multiblock. The current CEREC software and Red Camera were used to make the restorations. Even after 12 years in service, they are looking great.

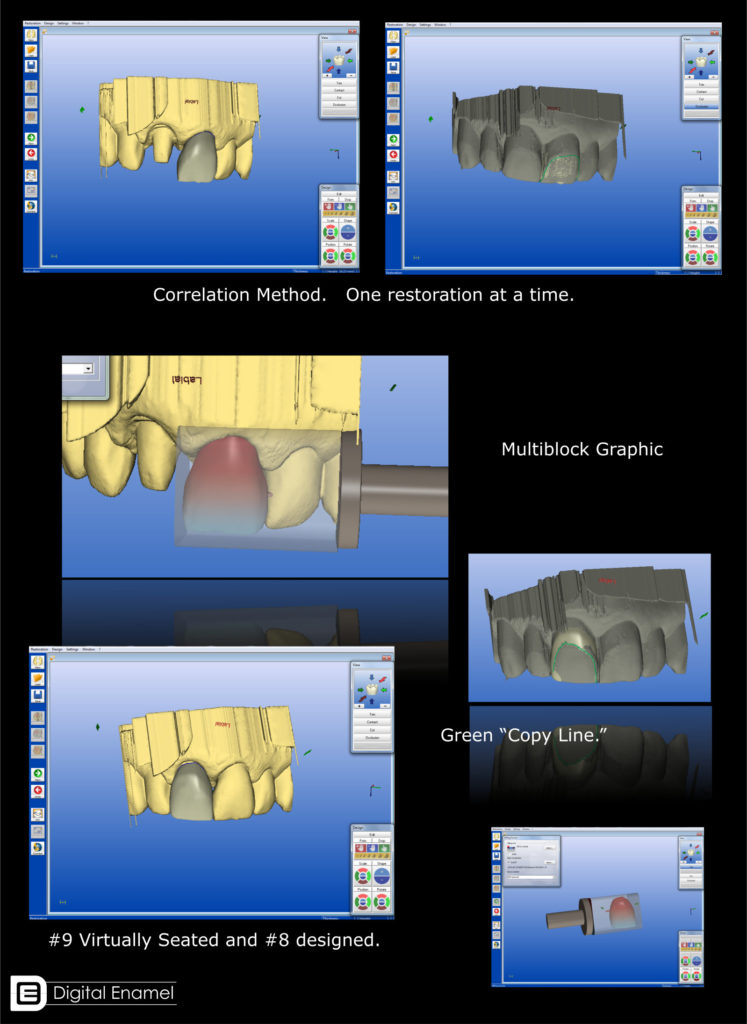

The software in 2007/8 was quite advanced with the ability of designing many types of single unit restorations. It had not developed enough to do them at the same time, however. Therefore, a process of “virtually seating” the design had to be completed. It was set, and unchangeable, while the adjacent restoration could be designed. In this particular case the Correlation Method was used to duplicate the surfaces of the prior restorations. This is the same as the current “Biocopy” process in CEREC. The software even showed the varying levels of translucency that the ceramic is known for.

The software in 2007/8 was quite advanced with the ability of designing many types of single unit restorations. It had not developed enough to do them at the same time, however. Therefore, a process of “virtually seating” the design had to be completed. It was set, and unchangeable, while the adjacent restoration could be designed. In this particular case the Correlation Method was used to duplicate the surfaces of the prior restorations. This is the same as the current “Biocopy” process in CEREC. The software even showed the varying levels of translucency that the ceramic is known for.

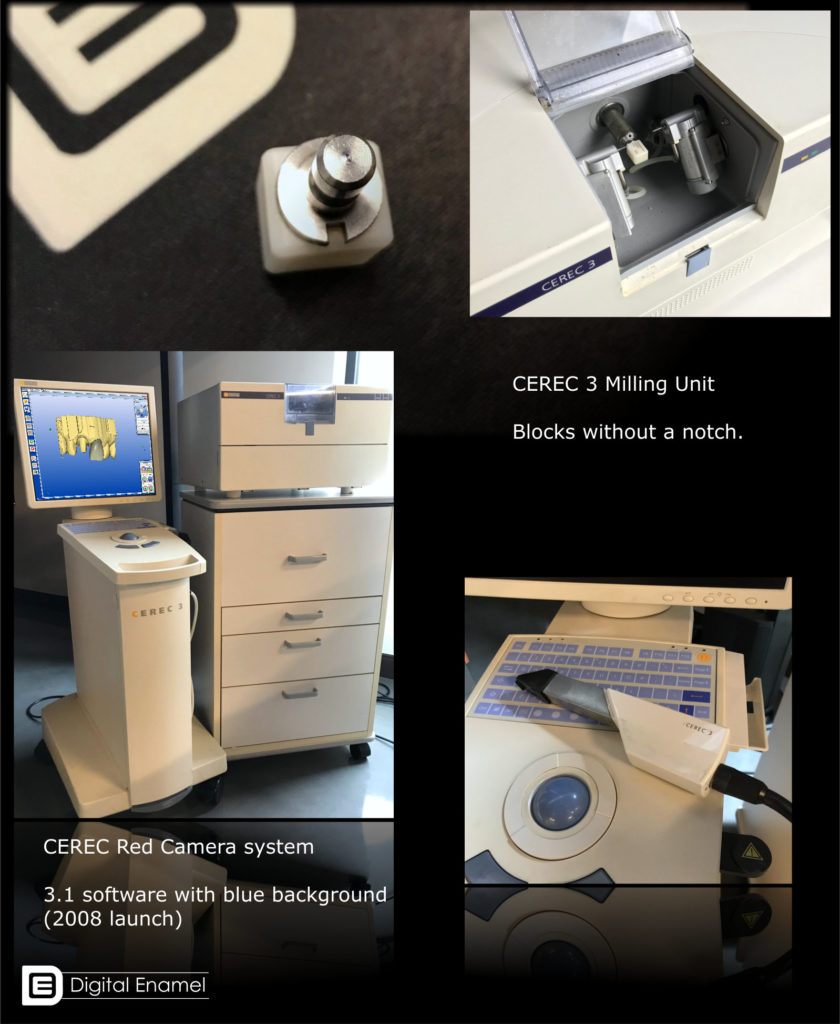

The “Compact Milling Chamber” was used to mill the block. It was not known as the “Compact” until the MCXL was launched later in 2008. It was just the “milling chamber.” While not as fast as our current MCXL’s it was quite the machine. It was slower, but hearty. It was a rare occurrence to have any problems with it. Completing multiple units with it made for a time constraint and there were many techniques established to overcome this limitation. The virtual seat actually made it convenient to get one milling while the next case was designed. This required opening another file for Cerec, as the virtually seated file was locked during milling.

The “Compact Milling Chamber” was used to mill the block. It was not known as the “Compact” until the MCXL was launched later in 2008. It was just the “milling chamber.” While not as fast as our current MCXL’s it was quite the machine. It was slower, but hearty. It was a rare occurrence to have any problems with it. Completing multiple units with it made for a time constraint and there were many techniques established to overcome this limitation. The virtual seat actually made it convenient to get one milling while the next case was designed. This required opening another file for Cerec, as the virtually seated file was locked during milling.

The milling chamber also used block mandrels that did not have a notch. The notch was later introduced to differentiate them for the MCXL and aid in the automatic tightening chuck.

Our online education platform is awesome! Hundreds of videos that help your day-to-day use of CEREC! Works directly through your Apple or Android devices!