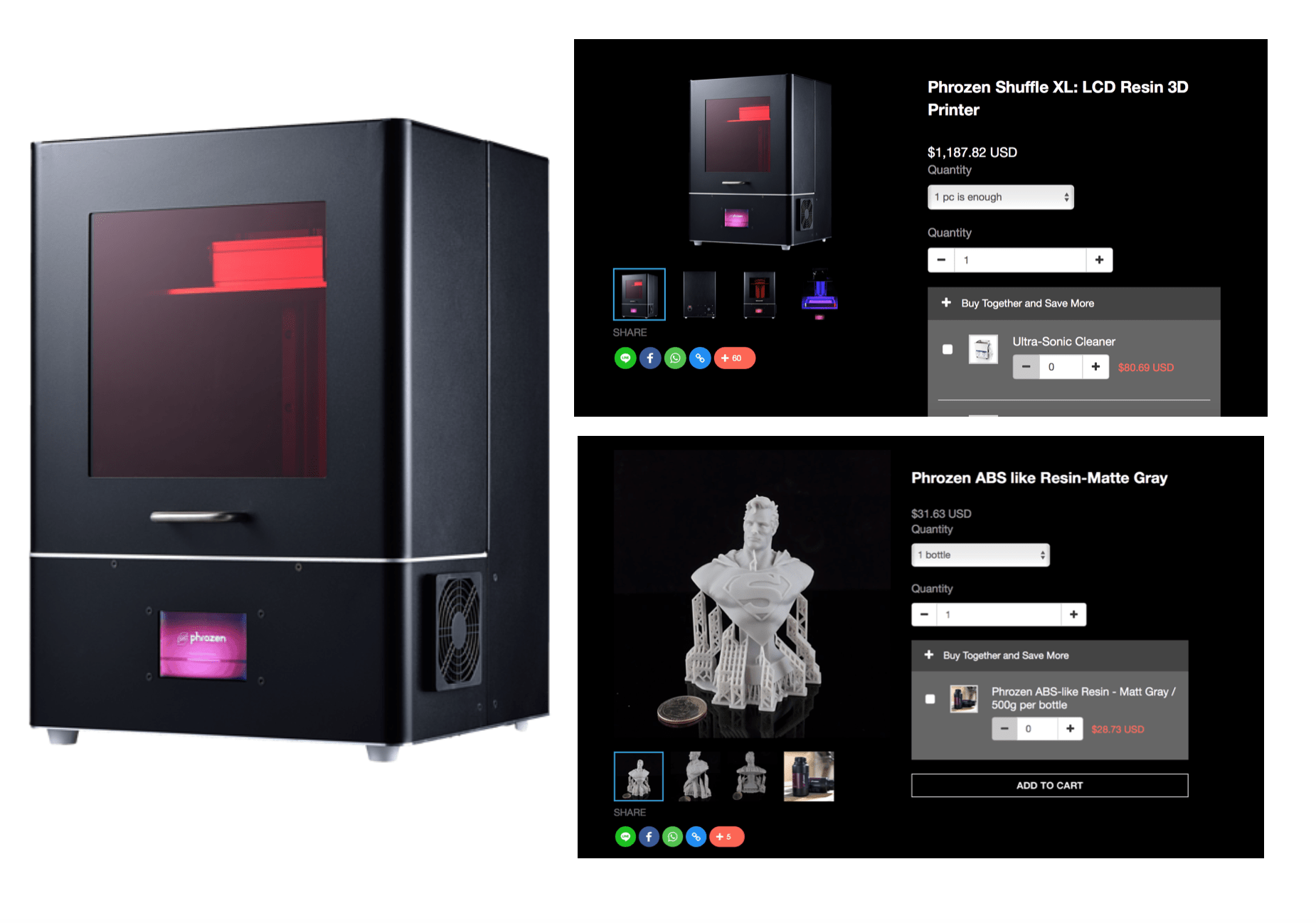

I really am loving the low cost printers from a company with a funny name, Phrozen. This is the 3rd printer I have bought from them and, although I am sticking to my guns on getting a Moonray or Form 2 for a production, dental office printer, I may change my tune with this one, at least for the more techie Dentist. The Phrozen XL has a really large build plate, 120 by 190mm in comparison, the Form 2 is 150 by 150 and the Moonray is 150 by 100. The price is great at $1200, and the Phrozen Gray is a really nice resin that sells for $63/L (31.50 per 500ml). The resolution is better than the other two at 75 microns is the XY vs 140 for the Form 2 and 100 for the Moonray. The question is, with the Shuffle at 47 microns with a really small build plate, can you do dies and analog models at 75? Well read on!

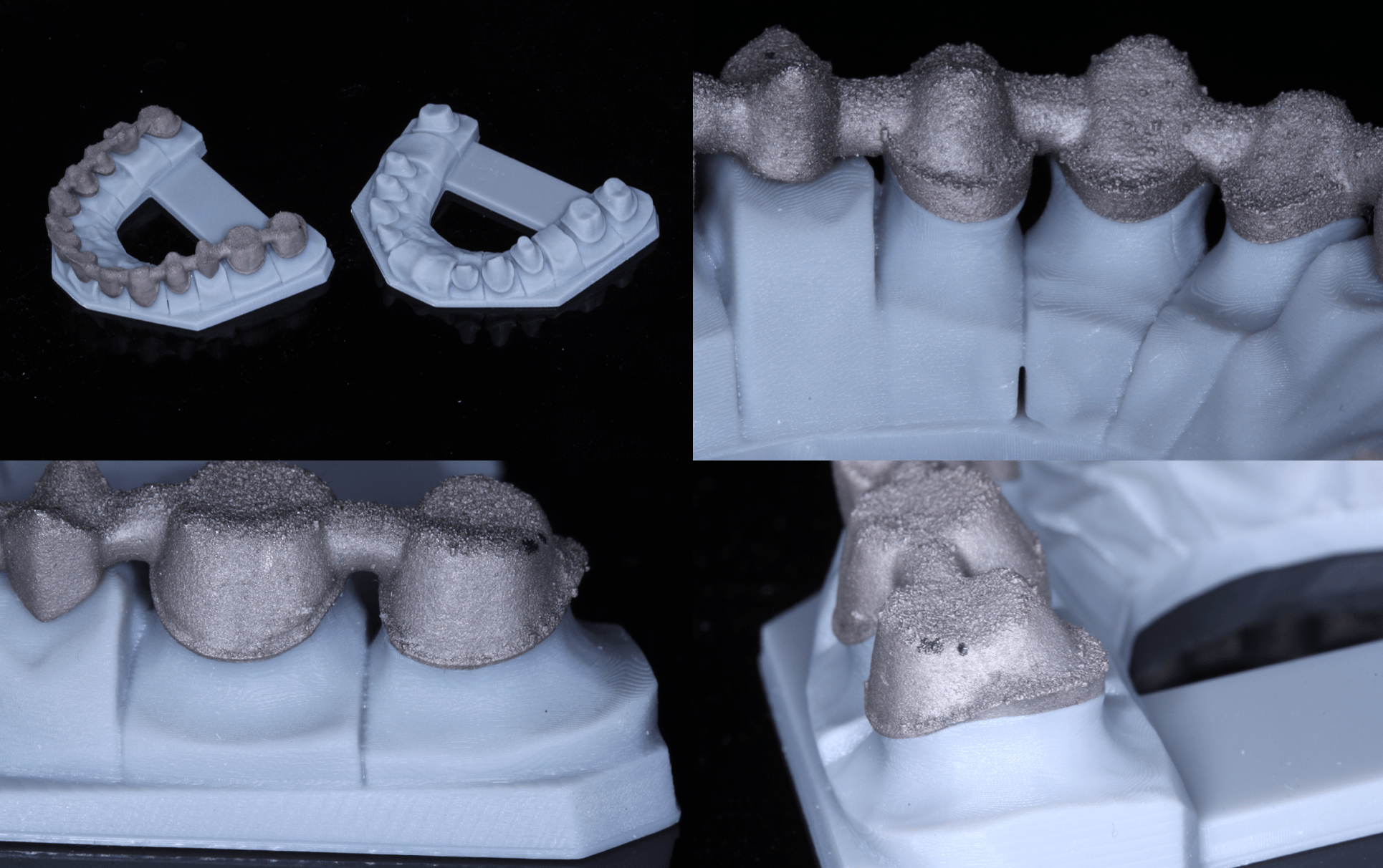

I wanted to check a few things with margins. First, are they closed. But Second, how accurate is a model printed on the edges vs one printed in the center, where most printers can always get accurate. Its the periphery that is hard. Phrozen uses an array of UV bulbs which they call a Para LED that is supposed to be accurate through out the enamors build plate. Well, the bridge that I had made to a standardized STL fit perfectly on a model in the center of the build vs the edges!! Thats a big deal with a low cost printer.

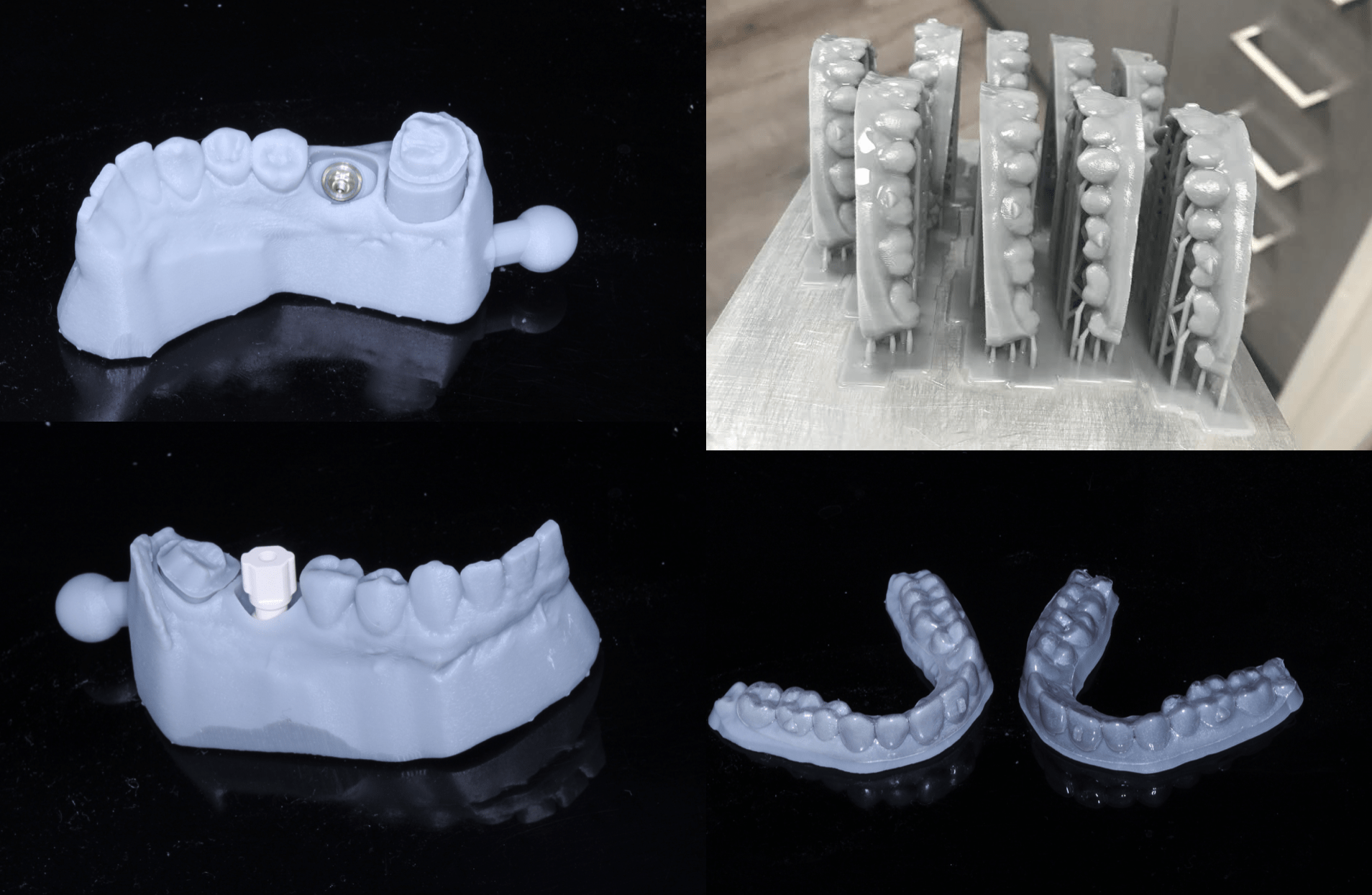

I printed a model at a gap between the die and the model at 100 micron gap (which the Phrozen shuffle can do) and 200 microns. Obviously the smaller the gap, the less “play”. The die on the XL did not seat at 100 microns but did at 200. I guess I could have tried 150 microns. The analog fit perfectly, there is no spacer setting for the analog. Next I tried printing a bunch of models and made aligners on a Moonray model and also an aligner on the Shuffle model, both fit great on wither model. This shows it can make aligner models just as well as higher priced printers.

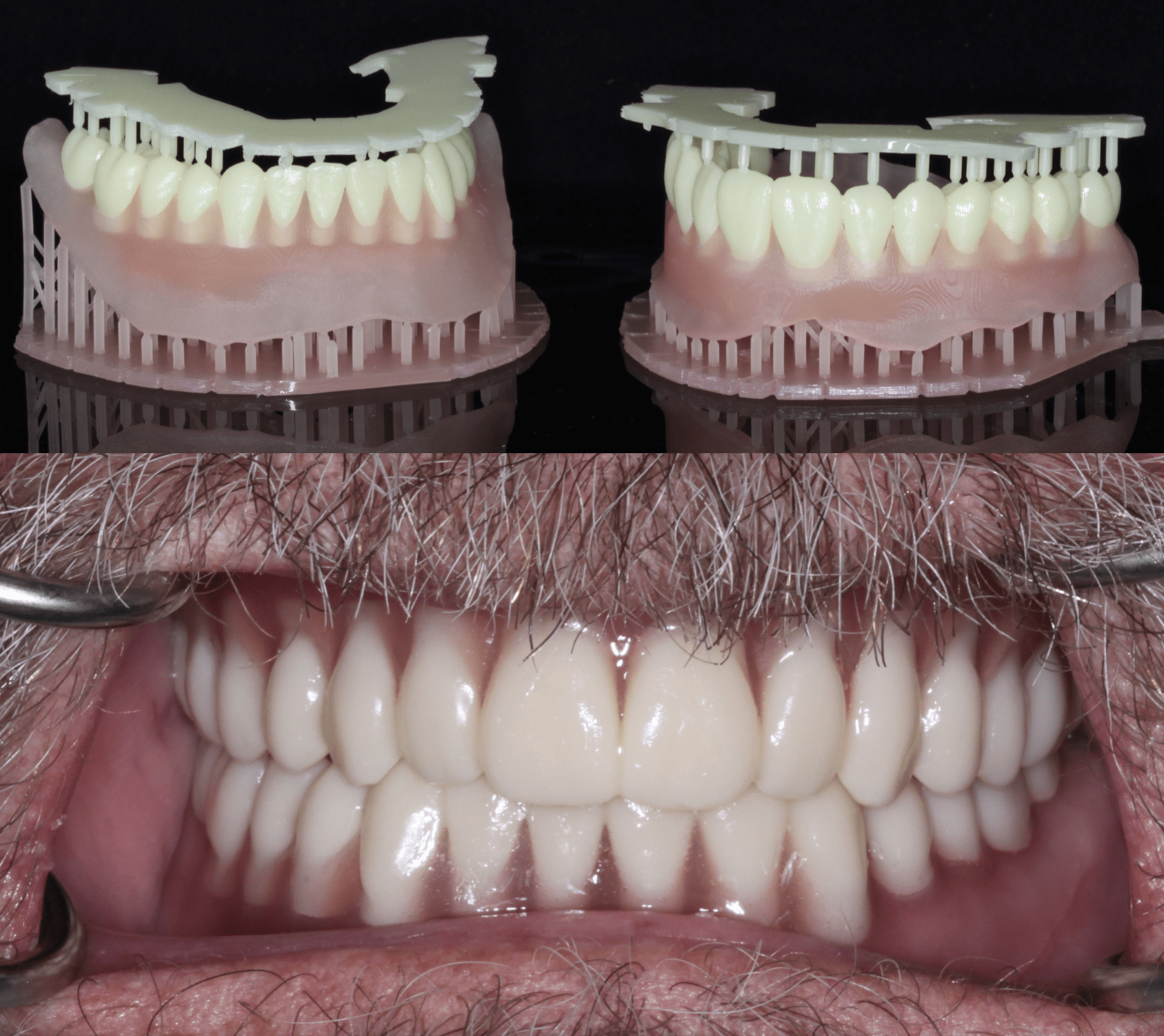

I’ll shoot a video, but the only drawback with the Shuffle printers, and the reason why I still recommend the Form 2 and Moonray for production dental offices, is the software. Supports and models need to be added and oriented in one software (Zenith or Chi Tu slicer), saved as an STL, then uploaded through a software called NanoDLP and a resin profile specified. I’m working on adapting my Phrozen Make profiles to the XL though. If you are a techie dentist and can jump through some hoops and save a few grand, this one is for you.

But you just can’t beat the price at $1200. I am hoping the guys at Phrozen come out with an all in one software, if they do that, they would be unstoppable in dentistry!!

I’ll bring the XL to Akron where I am doing a 3D Printing Party Jan 11-12. Come on down if you want to learn more about 3D Printing, how to make aligners, guides, night guards and dentures!!

Register Here for the 3D Printing Party!!